One Molesworth Street Dublin

Situated in a commanding location on the corner of Molesworth Street and Dawson Street in Dublin city centre, One Molesworth Street is a striking new building designed by Henry J Lyons Architects. Completed in 2018, they combined the finest contemporary materials and finishes to produce a design carefully sculpted to be sympathetic to its setting.

ARCHITECT BRIEF

Henry J Lyons asked us for a proposal for a bespoke designed impressive cluster light feature to sit within the grandeur of the double height reception area of One Molesworth. It needed to fill the space without overpowering it but also feel totally organic with minimal visible suspension cables. The materials used were required to compliment and blend with the proposed finishes for the reception area which were solid bronze, natural Travertine stone floors, Gold leaf, dark timber and a backlit Onyx stone reception desk.

OUR PROCESS

The first step was to settle on the style of pendant that would be the perfect fit for the cluster arrangement. After many suggestions to the architect, viewing of samples and much deliberation, we finally settled on the ‘14’ pendant by Canadian lighting manufacturer ‘Bocci’. There was to be a total of 49 pendants hung at varying heights in rows of 7. The 14 globe is an articulated, cast glass sphere with a frosted cylindrical void that houses a LED lamp. During the manufacturing process of these luminaires, glass is poured into a hemispherical mold. As the glass cools, a meniscus shape forms on the open face of the piece. Two of these pieces are joined to form an articulated sphere, with the two voids in the middle yielding a certain optical quality. A cylindrical void passes through both hemispheres and houses the light source. Individual pendants are visually subtle, but gain an atmospheric quality when multiplied and clustered in groups.

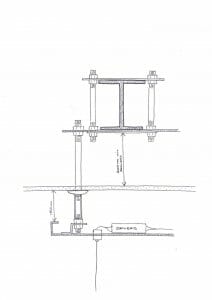

Step two was to design the support canopy that the pendants would be fixed to. This required a bespoke canopy to be manufactured as there was no ‘off the shelf’ options that would suit the architect’s vision. The canopy was also required to be fixed to the building sub-structure. The reason for this was that the combined weight of canopy plus the Bocci pendants including all the drivers and accessories had a combined weight totaling approximately 360kg. Because of the sheer weight and size of the installation we proposed to split the support canopy into 3 sections to aid installation on site. All drawings and specifications were produced in-house by our amazing design team. The canopy was manufactured locally in Kilkenny and powder coated in Carlow.

INSTALLATION

During the installation stage we worked on-site with the electrical contractor COBEC Engineering. Anything that could be pre-assembled in house in our Kilkenny workshop was carried out before delivery, to aid installation and minimise time spent on site. For example, all transformers were pre-wired and hidden within the body of the canopy and all fixings for the globes were pre-installed. Once delivered to site it was a matter of fixing the canopy supports to the building sub-structure, installing the canopy and then individually hanging each Bocci pendant at varying heights, to create the architects vision of an organic impressive cluster feature.

Installation took place on a working construction site so dust and dirt was a major issue to contend with to avoid staining the matt white finish to the canopy or the glossy Bocci globes.

The entire installation process took 4 people and 2 full days on site.