- Contact us to discuss our residential design packages

- Design

- Inspire

- About

- About

- Blog

- Deconstructing 06…Under Our Feet!

- April 25, 2021

- Monica Duggan

I don’t know why exactly but I’ve always had a love for real wood floors so I did feel this was the way we would eventually go even before we went looking.

When we bought our cottage, the first things I invested in were teak parquet flooring and a cast iron bath! Both of which I got from Kilkenny architectural salvage, a local antique warehouse.

When our builder i.e. my father-in-law first saw the floor, he nearly had a heartache! If you haven’t worked with reclaimed flooring before, it can be an absolute nightmare.

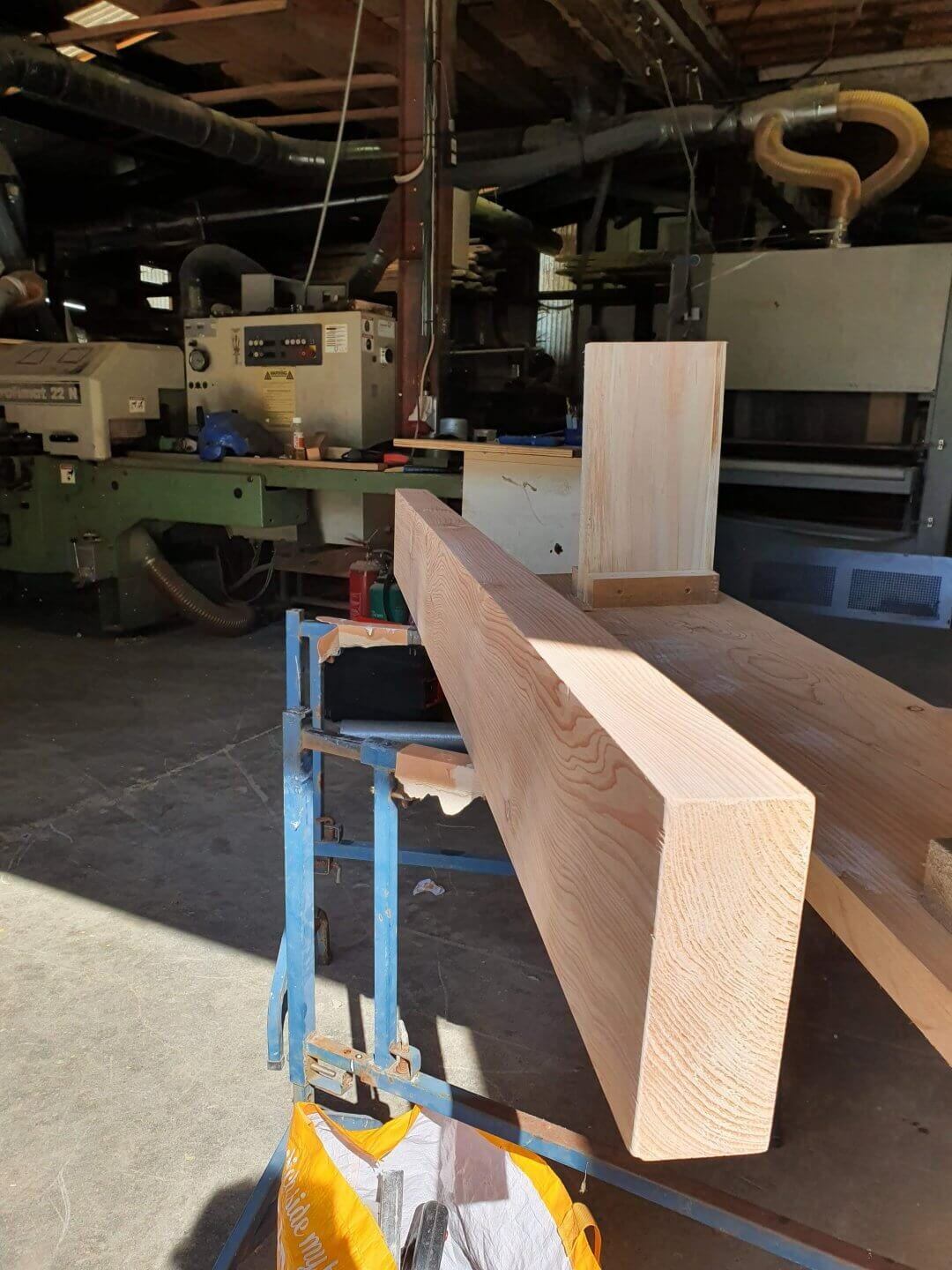

The contrast flooring. Inch Sawmills were right! Our flooring came from a convent in Abbeyleix, and yes, it needed a huge amount of work, even before we started to lay it. Firstly, we had to clean the bottom of each plank as there was left-over glue remaining from the convent. Once clean there were a few more steps to laying this type of flooring, and each of them took time, the last step being the most labour intensive. The original cottage flooring lay directly on dirt as is the case with most older buildings meaning cold seeped into the house from the ground. So instead of glue, we chose tar as our sealant, a material that helped to keep the cold out! We could have looked to re-concrete the floor but, with such low ceilings, we would have lost a few inches we could not afford. If anyone has ever worked with tar before you’ll know it is a really dirty job but in the end, it was worth it.

After our first experience, when it came to the extension we decided to be a bit more straightforward! I had done the rounds, looking at re-engineered wood, laminate, etc but none of them had the same feel as real wood. I meet suppliers a lot as part of my job here in Willie Duggan’s and once I see their factory and the passion they have for their craft, I usually fall in love with their art too! And that was no different when it came to choosing our flooring.

The original mill wheel at Inch I have known about Inch Sawmills for years, they are located in an idyllic spot along the river in Kilkenny just off a very popular walking trail so I’ve passed them many times. But when I arrived into their yard on a cold October day, met Eoin, and walked the yard, I was sold!

The mill has a rich history. It was in production up to 1656 when the mill took a sabbatical for about 200 years! The Brett family bought it over in 1886, now four generations later, Eoin is running the place with his father and still using the mill wheel to generate most of their electricity.

Inch Sawmills – crafts people going back generations. They were great to advise us on the different types of wood and what best to use. Beechwood is stunning, I loved the natural patterns of the spalted beech and had wanted to use it but given that it was meeting our parquet, Eoin advised against it warning us that the dark parquet meeting the beech would be overwhelming. He was right and it was something we wouldn’t have thought about ourselves.

Sustainability at it’s best! Lost for choice! - Monica's Newsletter

- Blog Post, flooring, Hard Wood Flooring, inchsawmills, Lighting, Lighting Design, Monica Duggan, newbuild, Parquet FLooring, Renovation, selfbuild, willie duggan

About Monica Duggan

Monica grew up with a screwdriver & bulb in her hands before she started to 'hassle' the boss! After gallivanting around the world & getting an education she worked in all areas of the business, and was a natural fit for developing Willie Duggan further. She does her best thinking struggling up a mountain, hiking a trail or beating herself up in the gym!

Browse by category

Browse by tag

- #IDSW2019

- 2019

- 2021

- 2022 Award Winners

- 48 volt track

- About Us

- Ambient Lighting

- Architect

- Art

- Arturo Alvarez

- Awards

- Bathrom

- Bathroom

- Bathroom Design

- Bathroom Lighting

- Baynetcap

- bedroom lighting

- Behind the Scenes

- Biophilia

- Biophilic Design

- Blanchardstown Shopping Centre

- Blog Post

- Blue

- Brands

- building materials

- bulbs

- Carton House

- church design

- Colour

- Comfort Lighting

- commercial

- commercial design

- Contract Interiors

- cost

- Cottage Design

- Creativity

- Deconstructing

- decorative lighting

- Denise O'Connor

- Design

- Design Team

- Details

- Dining Space Lighting

- Downlighting

- downlights

- E14

- electrician

- Electrics

- Emotion

- Emotional Lighting

- enviromentally friendly

- Estluz Laverd

- Exhibitions

- Experience

- experiential showroom

- Exterior Lighting

- external lighting

- eyelit65R

- Festoon Lighting

- Finalists

- Finances

- first fix

- five star hotel

- floor lamp

- Floor Light

- Floor Plan

- flooring

- functional lighting

- Garden

- Garden Lighting

- Getting the lighting right

- Glare

- GU10

- guide

- Haberdashery

- Hard Wood Flooring

- healthy lighting

- Heart of the home

- hidden lighting

- hints

- Home

- Home renovation

- house design

- Hypro

- Illuminated Furniture

- IMNDA

- importance of windows

- inchsawmills

- Interior Design

- Interior Lighting Design

- Interiors Trends

- International Dark Sky Week 2019

- internorm

- IP Rating

- Irish Times

- Ivela

- Jan Battles

- kitchen

- Kitchen Design

- Kitchen lighting

- Kitchen Squeeze

- Lampshades

- Landscape Lighting

- Layers of Light

- LED

- LEED

- Light

- light and health

- Light Art

- Light Brands

- Light Design

- Light Effects

- Light Fitting

- light masterplanning

- Light Pollution

- Light Technology

- lightbulbs

- Lighting

- Lighting Company

- lighting controls

- Lighting Design

- lighting designer

- Lighting Designers

- Lighting Plan

- Lighting Products

- lighting switches

- lighting tips

- LIT awards

- Living Space Lighting

- LND

- LZF

- Minimal Glare

- Monica Duggan

- mood lighting

- Motor Neurone Ireland

- munster joinery

- Nest

- new build

- New Year

- new york

- newbuild

- Newsletter

- night time lighting

- NYCxDESIGN

- Online Consultation

- Open Plan Space

- Our Team

- Outdoor

- Outdoor Lighting

- Parquet FLooring

- pendant light

- Pendants

- Piet Oudolf

- plastering

- plumbing

- Power of Switching

- Prolicht

- recessed lighting

- reducer

- reflections

- renovate

- Renovation

- Residential Lighting

- Residential lighting design

- retail

- Retro Fit

- riai

- salvaging

- scene setting

- Self build

- Self Build Newsletter

- selfbuild

- senator

- shadows

- sonos

- spacer

- Spotlights

- st bartholomews church

- Studio Italia

- sustainable

- sustainable building

- switching

- table lamp

- Table Light

- talalighting

- Task Lighting

- The Irish Times

- timber frame

- tips

- Trend

- tricks

- UGR

- Unified Glare Rating

- voliere

- willie duggan

- willieduggan

- Windows

- wiring

- Inspire